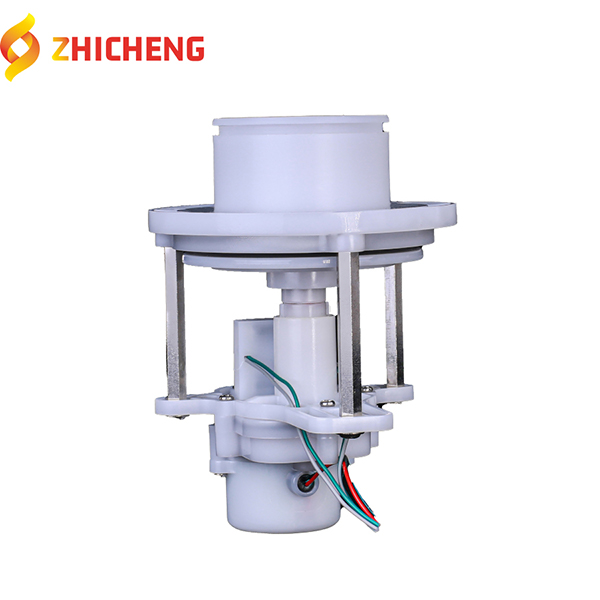

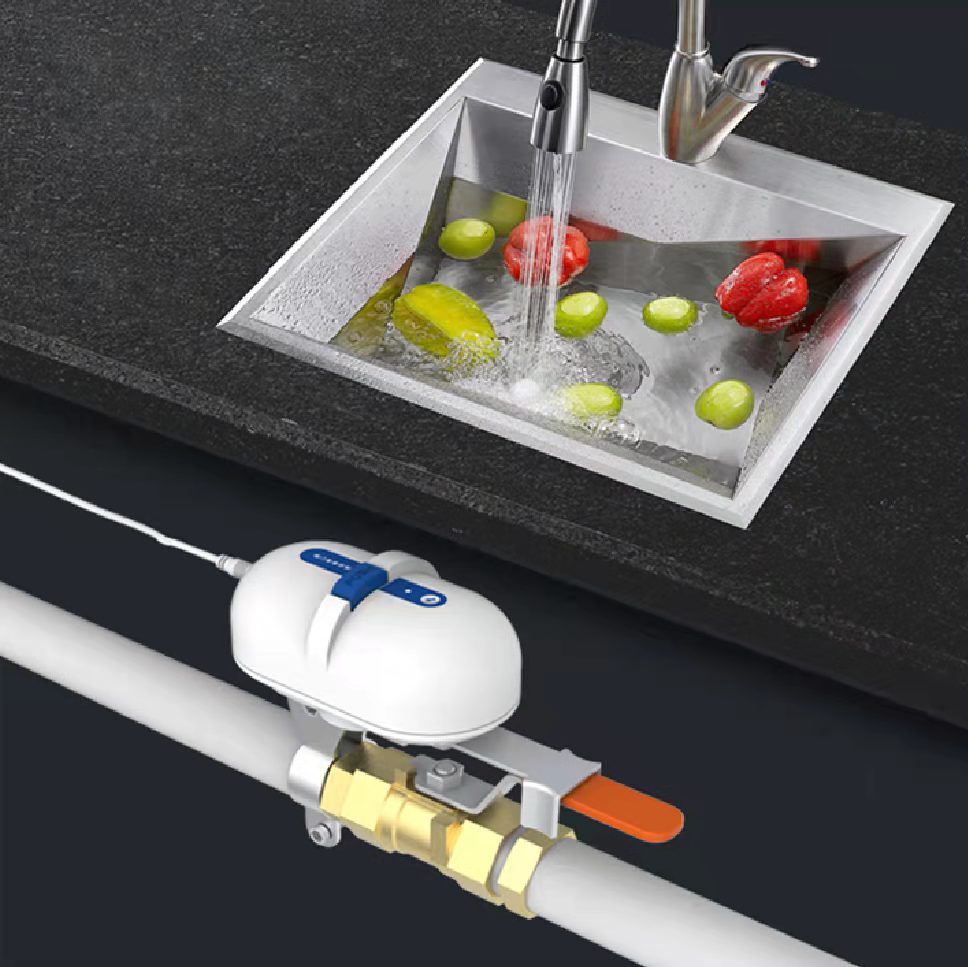

Smart valve controller

Smart valve controller-For a smart home

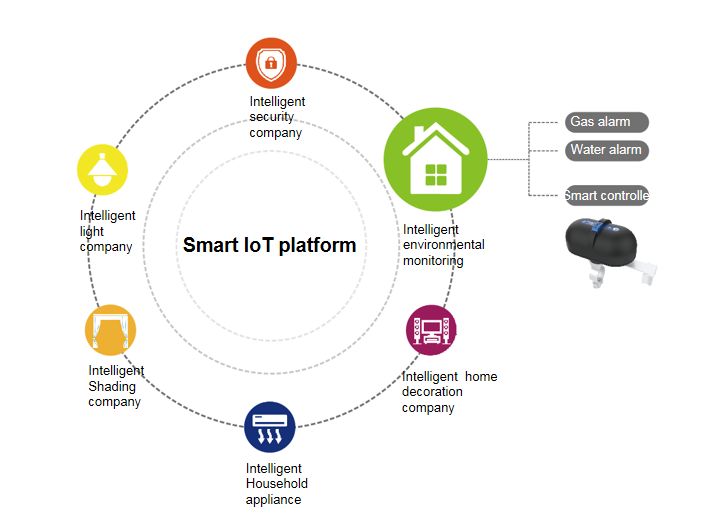

The samrt controller belongs to intelligent enviromental contolling equipment, which can connected with gas or water leakage alarm. when leakage happens, it will receive the signal from monitoring euipments such as gas or water alarm and close the valve in time.

Wire connected smart valve controller Advantages

1.Easy to be installed, You can quickly achieve intelligent control with our changing a new valve.

2.Unique look, It’s a better choice for a smart home.

3.Extended function, Reserve space for more intelligent improvment.

4.Lower cost, Wire connect type retains the core functionality and removes the extra expense.

5.Wired communication with various linkage alarms

Production Option

1. Standard type valve controller

2. a linked gas or water alarm

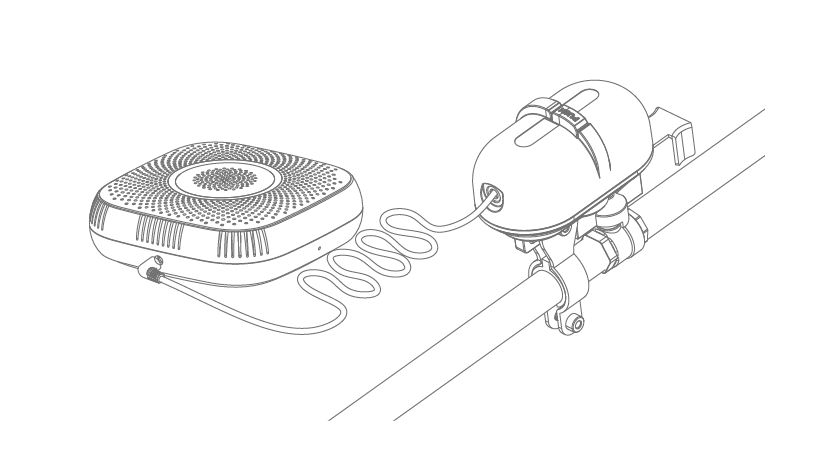

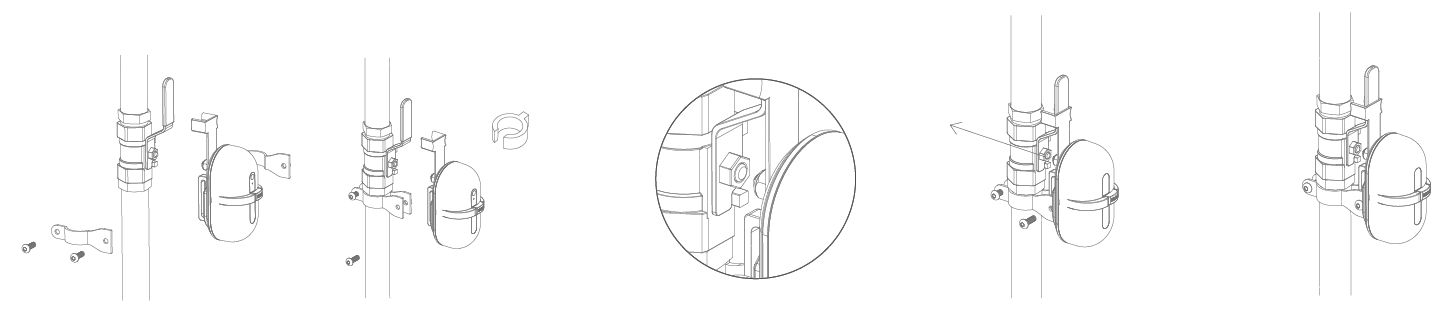

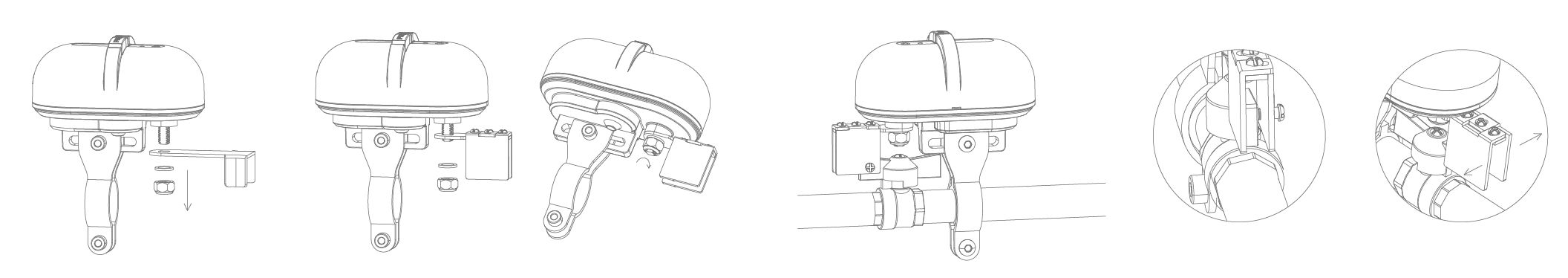

Valve controller’s installation

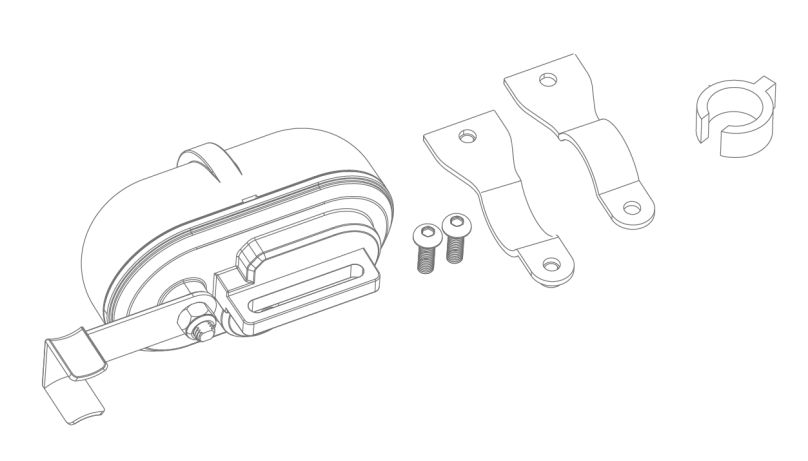

Valve controller *1

Bracket *1set

M6×30 screw *2

1/2” rubber ring *1(optional)

Hexagon wrench*1

when the tube is 1-inch, the rubber ring should be used inside of the bracket. when tube is 1/2'' or 3/4'', only to take off the rubber ring to fix the bracket throug the 2 screws

Adjust the controller position,

Ensure the output shaft of the manipulator

And the center line of the valve shaft

Coaxial line

less than 21mm tube, sub-accessories should be used.

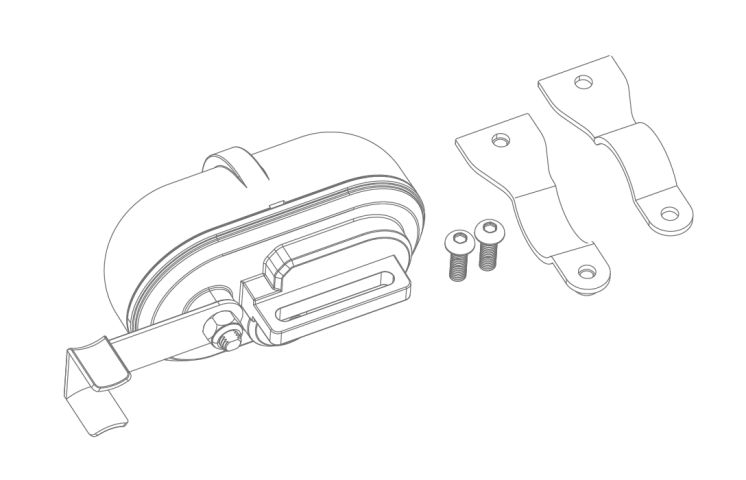

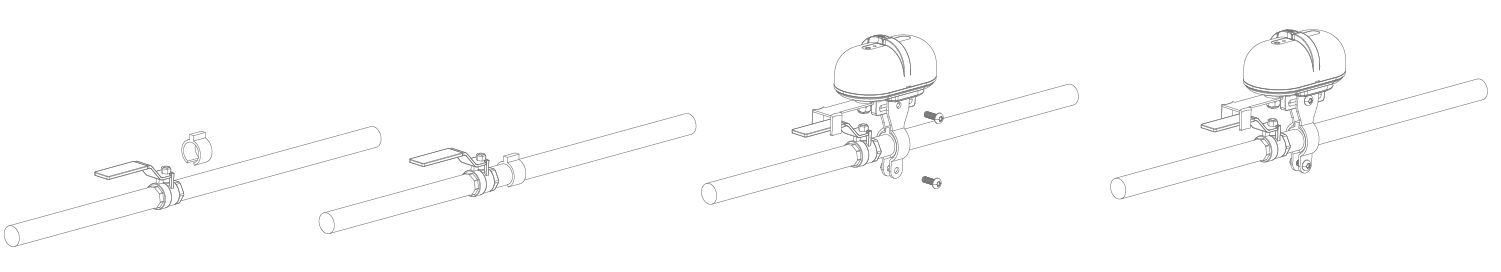

Valve controller *1

Bracket *1set

M6×30 screw *2

1/2” rubber ring *1(optional)

Hexagon wrench*1

1,put the rubber ring on the tube

2,fix the bracket on the rubber ring

3, tighten the screw.

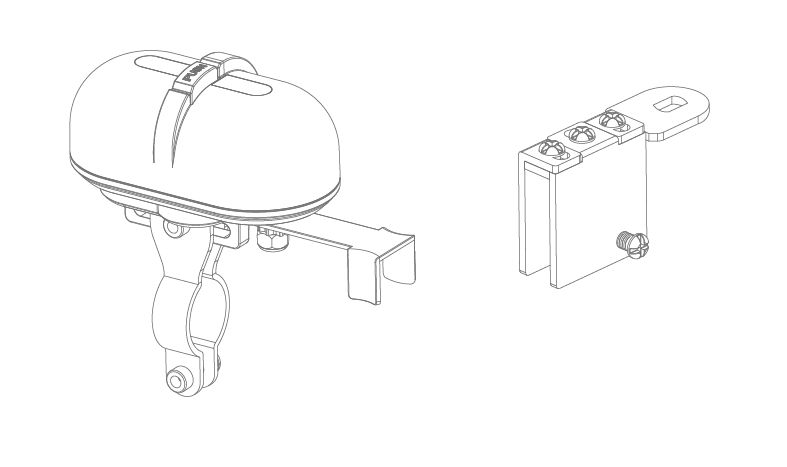

Butterfly valve

1,put of the wrench

2,change the butterfly valve wrench, and tighten the screw。

3, fix the wrench to the butterfly valve

Mark: through the screwn to adjust the width of the butterfly valve wrench

Tech Specs

| Operating temperature: | -10℃-50℃, |

| Operating environment humidity: | <95% |

| Operating voltage | 12V |

| Operating current | 1A |

| Max pressure | 1.6Mpa |

| torque | 30-60 N.m |

| Opening time | 5~10s |

| Closing time | 5~10s |

| Pipeline type | 1/2’ 3/4’ |

| Valve type | Flat wrench ball valve, butterfly valve |

Application

→ water valve controling

→ gas valve controling