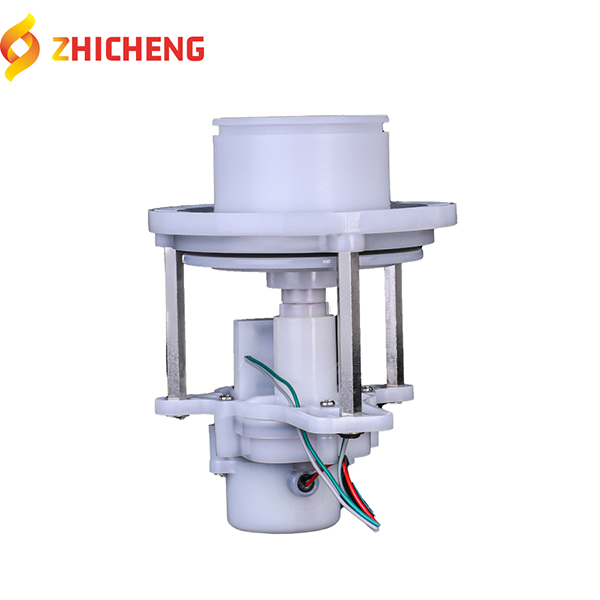

The principle of the gas meter motor valve is actually to use the power of the motor to control the flow of gas through an appropriate mechanical structure. Specifically, the motor valve on the gas meter mainly consists of two parts, one is the motor, and the other is the valve.

The first is the motor, which is the most critical component of the gas meter motor valve. An electric motor usually consists of two parts with different functions: the motor and the radiator. The electric motor is the power source of the gas meter motor valve. It can convert electrical energy into mechanical energy and control the valve by rotating the shaft. The radiator effectively dissipates heat from the motor to prevent circuit damage caused by overheating of the motor after long-term operation. Therefore, the motor of the gas meter motor valve must not only have high power, but also have good heat dissipation effect.

Next is the valve. The function of the valve is to control the flow direction and flow of gas, including opening and closing the gas channel. Common gas meter motor valves include ball valves, gate valves, butterfly valves, etc. The valves of gas meter motor valves generally have the characteristics of corrosion resistance, high temperature resistance and good sealing performance.

By combining the motor and the valve, gas control can be achieved. When gas is needed, the system will open the motor valve and flow the gas into the gas equipment to meet the demand. When there is no need to use gas, the system will close the motor valve and stop the flow of gas, thereby avoiding problems such as gas leakage and waste.

In short, the principle of the gas meter motor valve is to use the drive of the motor and the control of the valve to achieve effective management and control of the flow direction, flow and use of gas. This not only ensures the safe, efficient, and energy-saving use of gas but also improves the quality and efficiency of life and production.

Post time: Oct-30-2023