Manufacturer of China Gas Temperature-Sensing Valve 120-200 Degree Fryer Thermostat Gas Control Valve Wtih Thermocouple

We have by far the most highly developed manufacturing equipment, experienced and qualified engineers and workers, regarded high quality handle systems along with a friendly qualified revenue team pre/after-sales support for Manufacturer of China Gas Temperature-Sensing Valve 120-200 Degree Fryer Thermostat Gas Control Valve Wtih Thermocouple, We welcome new and previous customers from all walks of lifestyle to contact us for long run organization relationships and mutual achievements.

We have by far the most highly developed manufacturing equipment, experienced and qualified engineers and workers, regarded high quality handle systems along with a friendly qualified revenue team pre/after-sales support for China Gas Fryer Valve, Gas Control Valve, We have been always creating new technology to streamline the production, and offer goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We’ll offer you our best service to satisfy all your needs! Be sure to contact us right away!

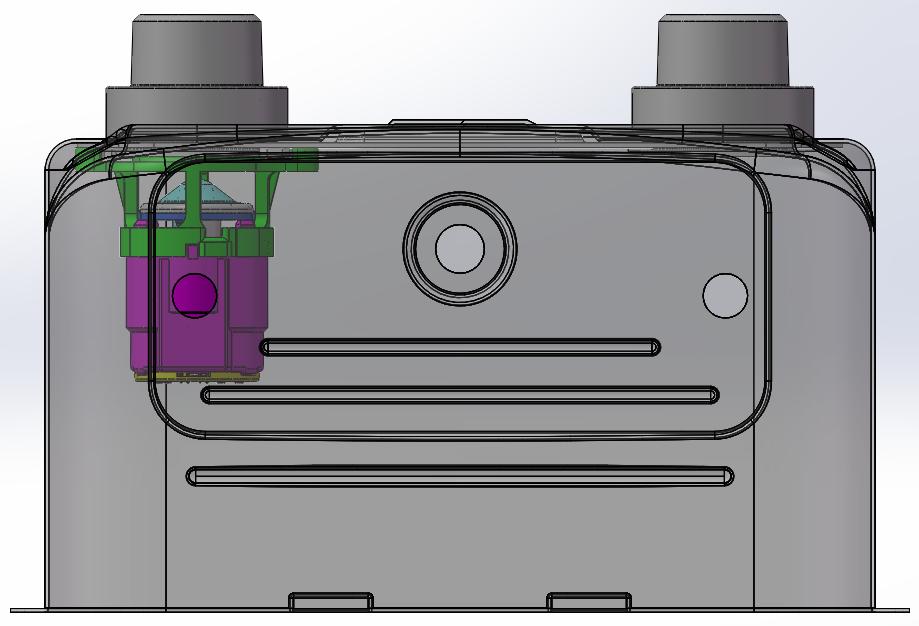

Installation location

The motor valve may be installed in the smart gas meter.

Product Advantages

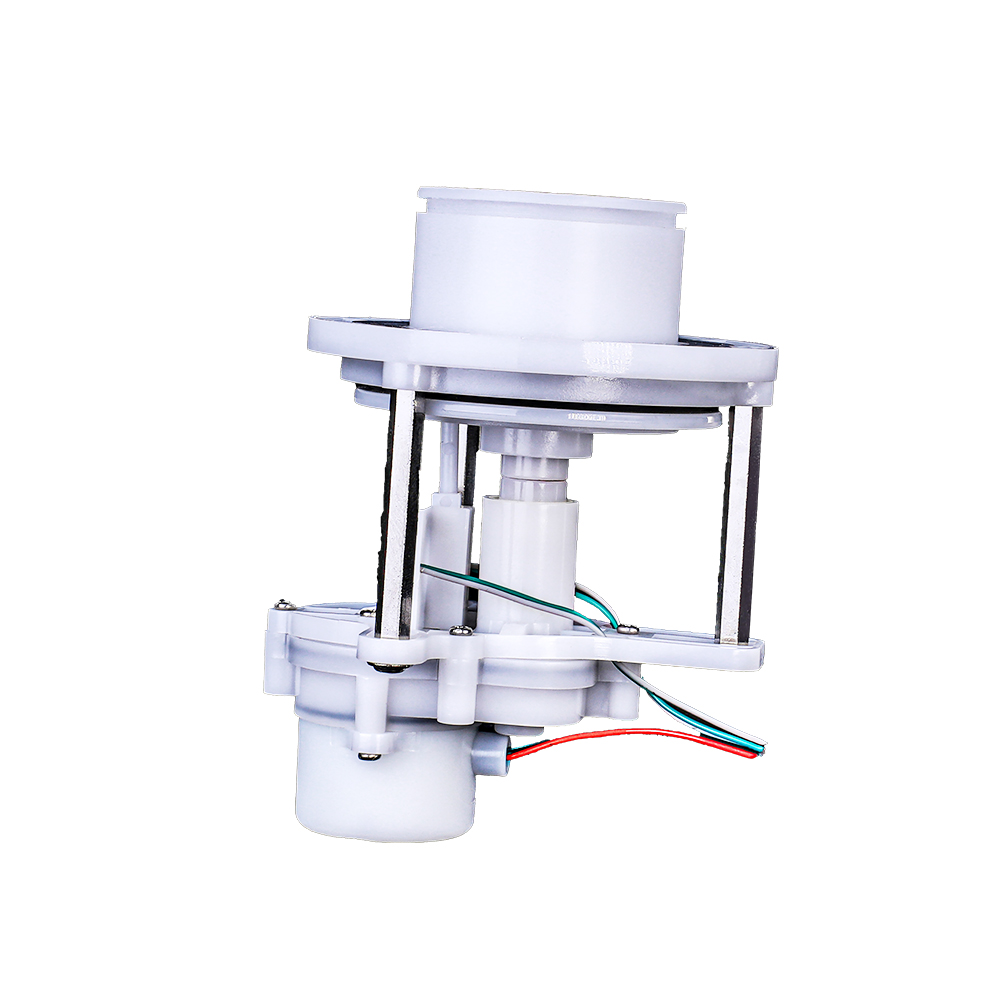

Built-in B& Motor Valve’s Advantages

1.Low pressure drop

2.Stable structure Max pressure can reach 200mbar

3.Small shape, easy installing

4.Low costs

Instruction For Use

1. The lead wire of this type of valve has three specifications: two-wire, four-wire or six-wire. The lead wire of the two-wire valve is only used as the valve action power line, the red wire is connected to positive (or negative), and the black wire is connected to negative (or positive) to open the valve (specifically, it can be set according to customer requierements). For four-wire and six-wir e valves, two of the wires (red and black) are the power supply wires for valve action, and the remaining two or four wires are status switch wires, which are used as signal output wires for open and closed positions.

2. Power supply time requirements: when opening/closing valve, after the detection device detects that the valve is in place, it needs to delay 2000ms before stopping the power supply, and the total operating time is about 4.5s.

3. The motor valve opening and closing can be judged by detecting the locked-rotor current in the circuit. The locked-rotor current value can be calculated according to the working cut-off voltage of the circuit design, which is only related to the voltage and resistance value.

4. It is recommended that the minimum DC voltage of the valve should not be less than 3V. If the current limit design is in the valve’s process of opening and closing, the current limit value should not be less than 120mA.

Tech Specs

| Items | requirements | Standard |

|

Working medium |

Natural gas,LPG |

|

|

Flow range |

0.016~6m3/h |

|

|

Pressure Drop |

0~20KPa |

|

|

Meter suit |

G6/G10/G16/G25 |

|

|

Operating voltage |

DC3~3.9V |

|

|

ATEX |

ExicⅡBT4 Gc |

EN 16314-2013 7.13.4.3 |

|

Operating temperature |

-25℃~60℃ |

EN 16314-2013 7.13.4.7 |

|

Relative humidity |

5%~90% |

|

|

Leakage |

2KPa or 7.5ka <1L/h |

EN 16314-2013 7.13.4.5 |

|

Motor electric performance |

20±10%Ω/16±2mH |

|

|

Current-limited resistance |

12±1%Ω |

|

|

Max current |

≤130mA(DC3.9V) |

|

|

opening time |

≤4.5s(DC3V) |

|

|

Closing time |

≤4.5s(DC3V) |

|

|

Pressure loss |

With meter case≤200Pa |

EN 16314-2013 7.13.4.4 |

|

endurance |

≥10000 times |

EN 16314-2013 7.13.4.8 |

|

Installation location |

Inlet/outlet |

We have by far the most highly developed manufacturing equipment, experienced and qualified engineers and workers, regarded high quality handle systems along with a friendly qualified revenue team pre/after-sales support for Manufacturer of China Gas Temperature-Sensing Valve 120-200 Degree Fryer Thermostat Gas Control Valve Wtih Thermocouple, We welcome new and previous customers from all walks of lifestyle to contact us for long run organization relationships and mutual achievements.

Manufacturer of China Gas Fryer Valve, Gas Control Valve, We have been always creating new technology to streamline the production, and offer goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We’ll offer you our best service to satisfy all your needs! Be sure to contact us right away!