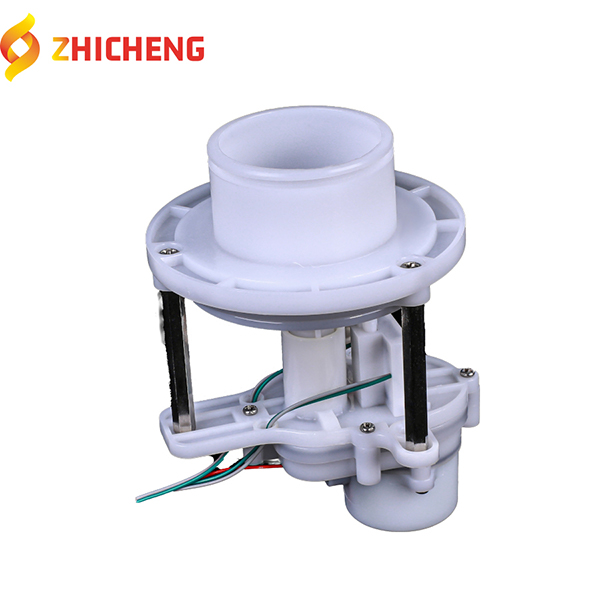

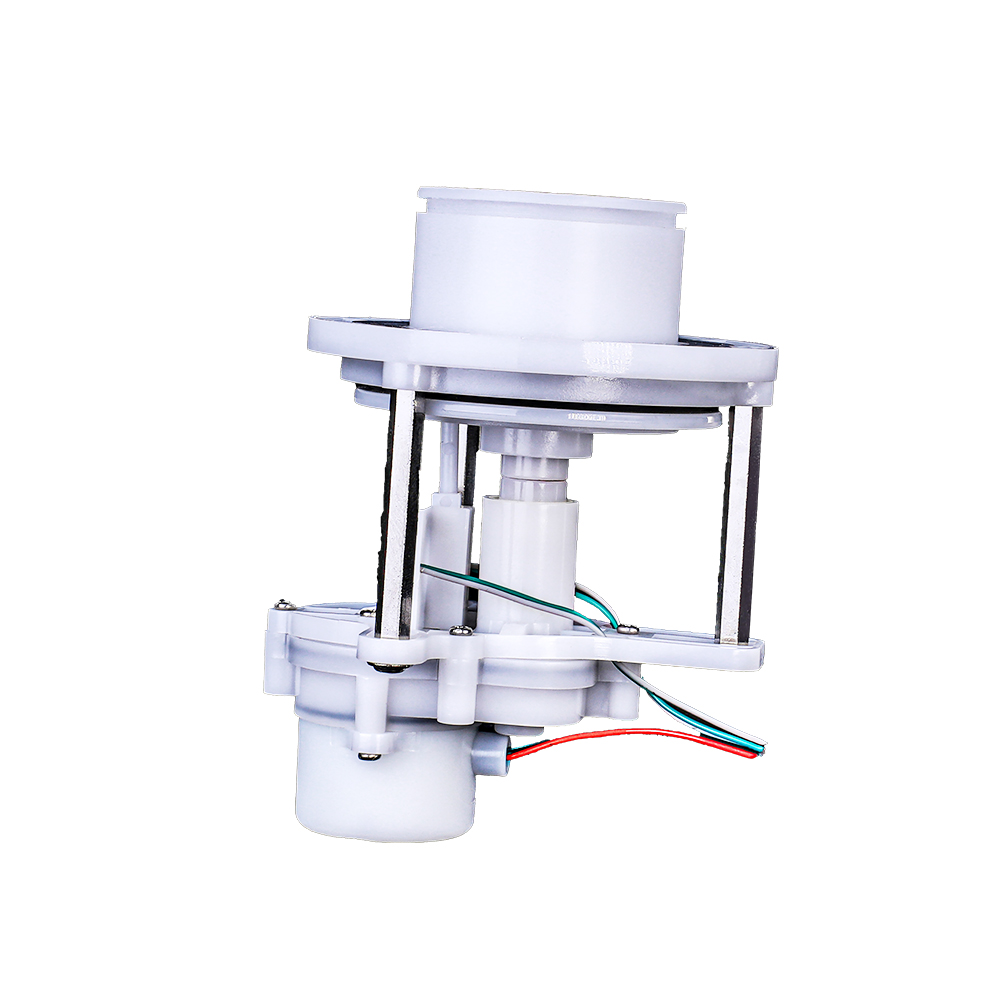

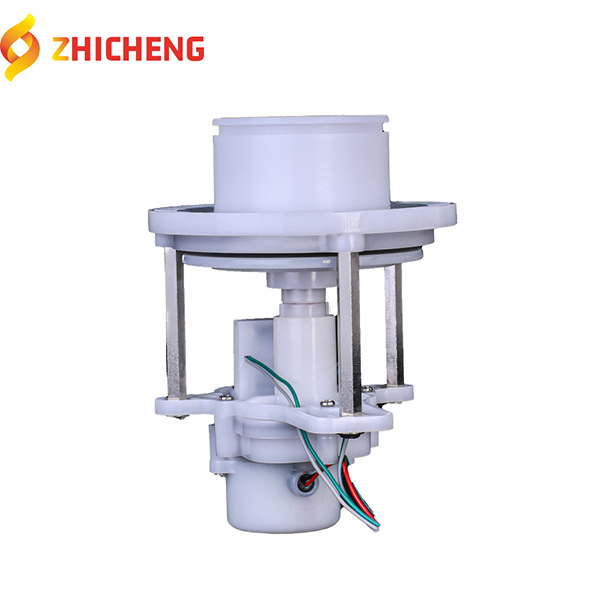

Built-in Screw Motor Valve for Smart Gas meter

Installation location

The motor valve may be installed in the smart gas meter.

Product Advantages

Built-in screw Motor Valve’s Advantages

1.Low pressure drop

2.Stable structure Max pressure can reach 150mbar

3.Small shape, easy installing

4.Low costs

Instruction For Use

1.This type of valve has two lead wires to supply power to the valve. The red wire is connected to positive power (or negative power), and the black wire is connected to negative power (or positive power) to open the valve (specifically, it can be set according to customer needs).

2.The minimum drive voltage of the valve shall not be lower than 3V. If the current limit design is in the process of opening and closing the valve, the current limit value shall not be lower than 130mA

3.The motor valve opening and closing can be judged by detecting the locked-rotor current in the circuit. The locked-rotor current value can be calculated according to the working cut-off voltage of the circuit design, which is only related to the voltage and resistance value.

Tech Specs

| Items | requirements | Standard |

|

Working medium |

Natural gas,LPG |

|

|

Flow range |

0.016~6m3/h |

|

|

Pressure Drop |

0~15KPa |

|

|

Meter suit |

G1.6/G2.5 |

|

|

Operating voltage |

DC3~3.9V |

|

|

ATEX |

ExicⅡBT4 Gc |

EN 16314-2013 7.13.4.3 |

|

Operating temperature |

-25℃~60℃ |

EN 16314-2013 7.13.4.7 |

|

Relative humidity |

5%~90% |

|

|

Leakage |

2KPa or 7.5ka <1L/h |

EN 16314-2013 7.13.4.5 |

|

Motor electric performance |

21±10%Ω/14±2mH |

|

|

Current-limited resistance |

9±1%Ω |

|

|

Max current |

≤140mA(DC3.9V) |

|

|

opening time |

≤0.8s(DC3V) |

|

|

Closing time |

≤0.8s(DC3V) |

|

|

Pressure loss |

With meter case≤200Pa |

EN 16314-2013 7.13.4.4 |

|

endurance |

≥10000次 |

EN 16314-2013 7.13.4.8 |

|

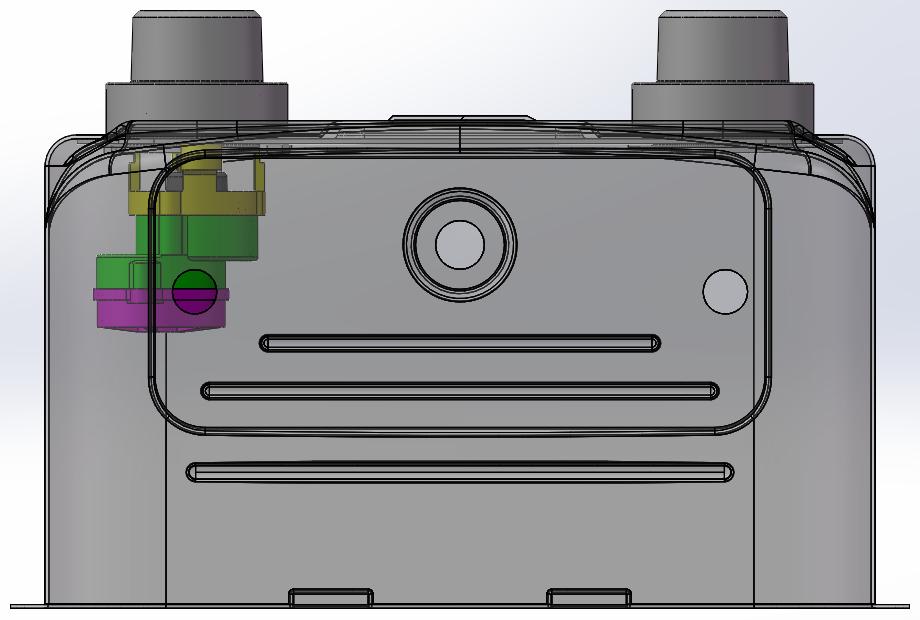

Installation location |

Inlet |